QR Code

Tungkol sa atin

Mga produkto

Makipag-ugnayan sa amin

Telepono

Fax

+86-579-87223657

E-mail

Address

Wangda Road, Ziyang Street, Wuyi County, Jinhua City, Zhejiang Province, China

Ang Silicon epitaxy, EPI, epitaxy, epitaxial ay tumutukoy sa paglaki ng isang layer ng kristal na may parehong direksyon ng kristal at iba't ibang kapal ng kristal sa isang solong mala -kristal na silikon na substrate. Ang teknolohiyang paglago ng epitaxial ay kinakailangan para sa paggawa ng mga sangkap na semiconductor discrete at integrated circuit, dahil ang mga impurities na nilalaman sa mga semiconductors ay kasama ang N-type at P-type. Sa pamamagitan ng isang kumbinasyon ng iba't ibang mga uri, ang mga aparato ng semiconductor ay nagpapakita ng iba't ibang mga pag -andar.

Ang paraan ng paglago ng epitaxy ng silikon ay maaaring nahahati sa epitaxy ng phase ng gas, likidong phase epitaxy (LPE), solid phase epitaxy, pamamaraan ng paglago ng singaw ng singaw ng kemikal ay malawakang ginagamit sa mundo upang matugunan ang integridad ng lattice.

Karaniwang kagamitan ng epitaxial na silikon ay kinakatawan ng kumpanya ng Italya na LPE, na mayroong pancake epitaxial hy pnotic tor, bariles type hy pnotic tor, semiconductor hy pnotic, wafer carrier at iba pa. Ang diagram ng eskematiko ng hugis-bariles na epitaxial hy pelector reaksyon ng silid ay ang mga sumusunod. Ang Vetek semiconductor ay maaaring magbigay ng hugis-bariles na wafer epitaxial hy pelector. Ang kalidad ng SIC coated hy pelector ay napaka -mature. Kalidad na katumbas ng SGL; Kasabay nito, ang Vetek Semiconductor ay maaari ring magbigay ng silikon na epitaxial reaksyon ng kuwarts na kuwarts na nozzle, quartz baffle, bell jar at iba pang kumpletong mga produkto.

![]()

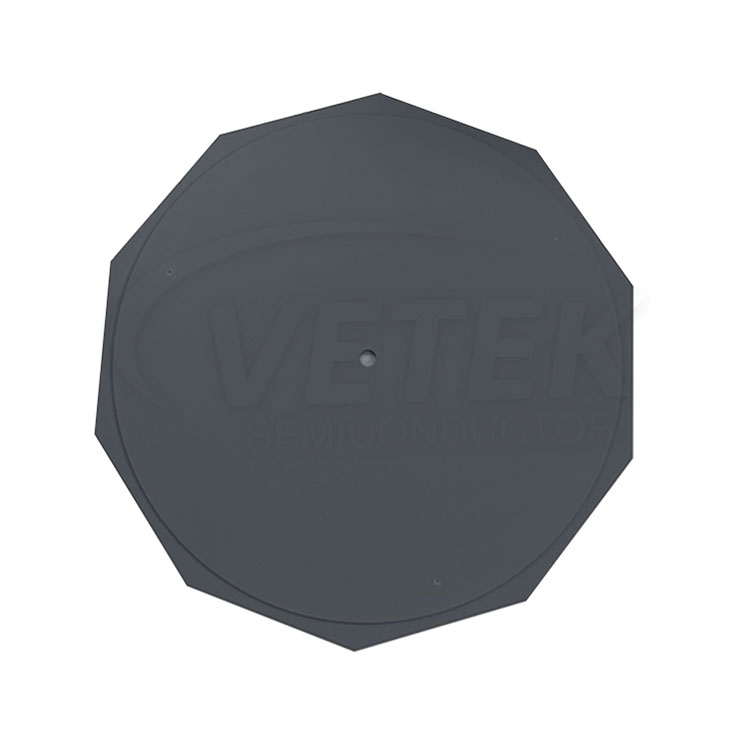

SIC Coated Graphite Barrel Susceptor para sa EPI

SIC Coated Graphite Barrel Susceptor para sa EPI  SIC Coated Barrel Susceptor

SIC Coated Barrel Susceptor  CVD SIC Coated Barrel Susceptor

CVD SIC Coated Barrel Susceptor  LPE kung set ng tagasuporta ng EPI

LPE kung set ng tagasuporta ng EPI

![]()

![]() Sic coating monocrystalline silikon epitaxial tray

Sic coating monocrystalline silikon epitaxial tray  SIC Coated Support para sa LPE PE2061S

SIC Coated Support para sa LPE PE2061S  Graphite umiikot na suporta

Graphite umiikot na suporta

Veteksemicon silicon epitaxy solutions are your strategic procurement choice for advanced semiconductor wafer processing, particularly in CMOS, power devices, and MEMS applications. As a key process in wafer engineering, silicon epitaxy (Si Epi) involves the precise deposition of a crystalline silicon layer on top of a polished silicon wafer, offering superior control of doping profiles, defect density, and layer thickness.

Veteksemicon provides epitaxy-ready susceptor parts and reactor components used in Epi CVD systems, supporting both atmospheric and reduced pressure processes. Our product lineup includes silicon epitaxy susceptors, carrier rings, and coated wafer holders, optimized for compatibility with tools from Applied Materials, ASM, and Tokyo Electron (TEL).

Silicon epitaxy plays a critical role in producing ultra-thin junctions, strained silicon layers, and high-voltage isolation structures. Our materials and parts are engineered for high-purity, uniform thermal distribution, and anti-contamination performance during n-type and p-type epitaxial growth.

Closely associated terms include epitaxial wafer, in-situ doping, epitaxy-ready SiC coatings, and epi reactor parts, which support the entire upstream and downstream process of silicon-based IC fabrication.

Discover more about Veteksemicon’s silicon epitaxy support solutions by visiting our product detail page or contacting us for technical consultation and part customization.

+86-579-87223657

Wangda Road, Ziyang Street, Wuyi County, Jinhua City, Zhejiang Province, China

Copyright © 2024 Vetek Semiconductor Technology Co, Ltd All Rights Reserved.

Links | Sitemap | RSS | XML | Privacy Policy |